All about Sheet Metal Laser Cutter

All about Sheet Metal Laser Cutter

Blog Article

With regards to fashionable production, the precision and efficiency of laser cutting engineering are really sport-changing. Laser chopping machines have revolutionized industries by providing a means of cutting supplies with unparalleled precision. In case you’ve ever marveled for the intricate patterns on metallic or wondered how elaborate designs are generated so seamlessly, it’s usually the do the job of an industrial laser chopping machine.

Enable’s start with the basic principles: a laser cutter is actually a Software that makes use of a laser beam to chop components. This beam is unbelievably focused and generates substantial temperatures to soften or vaporize the material, generating specific cuts. In contrast to classic methods, which might use mechanical blades, a laser cutter provides a volume of accuracy that is almost unmatched. Visualize attempting to carve a fragile sample having a hammer—Obviously, a laser cutter is a good deal extra refined!

Industrial laser reducing will take this technological know-how to the next degree, offering alternatives for giant-scale operations. These machines are developed to deal with significant elements and superior production volumes, ensuring that even the most demanding projects are completed with higher effectiveness. Think about it as being the distinction between utilizing a precision knife for sensitive paper crafts and a strong noticed for slicing as a result of thick Wooden.

The 2-Minute Rule for Precision Laser Cutting

On this planet of CNC laser reducing, the “CNC” stands for Pc Numerical Command. This technological know-how permits automated and extremely specific cuts by adhering to digital layouts. In case you’ve ever made use of a pc to draw and then viewed that drawing come to lifestyle, CNC laser chopping operates in a similar way, translating electronic patterns into Actual physical cuts. It’s like using a virtual designer Along with the precision of a laser.

On this planet of CNC laser reducing, the “CNC” stands for Pc Numerical Command. This technological know-how permits automated and extremely specific cuts by adhering to digital layouts. In case you’ve ever made use of a pc to draw and then viewed that drawing come to lifestyle, CNC laser chopping operates in a similar way, translating electronic patterns into Actual physical cuts. It’s like using a virtual designer Along with the precision of a laser.Some Known Incorrect Statements About Laser Cutting Machine

Precision laser slicing is just not nearly creating cuts; it’s about creating them right each and every time. The laser is often modified to attain different depths and widths, making sure that each Lower is exactly where it ought to be. That is vital for applications where by even a slight deviation may lead to substantial challenges. Imagine it like a surgeon’s scalpel, where precision is not simply crucial but absolutely important.

Precision laser slicing is just not nearly creating cuts; it’s about creating them right each and every time. The laser is often modified to attain different depths and widths, making sure that each Lower is exactly where it ought to be. That is vital for applications where by even a slight deviation may lead to substantial challenges. Imagine it like a surgeon’s scalpel, where precision is not simply crucial but absolutely important.Laser reducing equipment is available in numerous varieties, Each and every tailored to distinct requirements. Irrespective of whether You'll need a small desktop design for passion assignments or a large industrial machine for manufacturing facility use, there’s a laser reducing Alternative on the market for yourself. These devices range in energy, pace, and abilities, so it’s vital that you pick the correct just one for your distinct software.

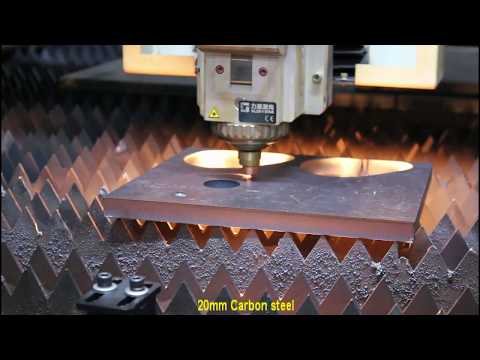

Sheet metal laser cutters undoubtedly are a special category of laser chopping equipment designed specifically for chopping metallic sheets. They are widely Employed in industries ranging from automotive to aerospace because of their capacity to tackle metal with precision and pace. Photo a sheet of metallic like a blank canvas, plus the laser cutter given that the artist who creates advanced and delightful patterns with extraordinary accuracy.

Laser reducing expert services are another essential aspect of this know-how. Not everyone requirements to invest in their particular laser slicing device, particularly if they only need to have occasional cuts or absence the Room for these kinds of devices. A lot of corporations present laser slicing companies in which you can ship your patterns and also have them Reduce with higher precision. It’s like outsourcing your artwork to a skilled Experienced.

Laser chopping devices combine a variety of elements to deliver the specified effects. With the laser supply for the cutting mattress, plus the Management computer software, each part of the process performs with each other to ensure a flawless Procedure. It’s somewhat like a symphony orchestra, wherever Every single musician has a specific purpose, and only by Functioning together do they develop a harmonious efficiency.

When it comes to laser reducing engineering, the evolution has been swift and extraordinary. In the beginning employed predominantly for reducing metals, these equipment now deal with a wide array of supplies which include plastics, Wooden, and in some cases fabrics. This flexibility helps make laser slicing technologies a worthwhile tool in a great number of industries. Consider having a Swiss Army knife which can deal with virtually any product—This can be what present day laser chopping technologies delivers.

The precision of laser chopping equipment is truly exceptional. They could Slice materials to inside microns in the meant style and design, making sure that even by far the most intricate aspects are preserved. This level of precision is particularly beneficial in industries in which actual measurements are critical. Imagine it as being the distinction between know more a customized go well with and off-the-rack garments—the in shape is simply best anytime.

4 Simple Techniques For Laser Cutting Systems

One more benefit of laser reducing know-how is its efficiency. Not like common reducing approaches Which may demand many actions or equipment, laser chopping often completes the activity in a single go. This don't just accelerates creation but will also reduces materials squander. It’s like using a superior-speed prepare that will get you to the desired destination quickly and effectively without any needless stops.While in the context of industrial purposes, the robustness of laser chopping equipment is crucial. These machines are constructed to endure the needs of constant operation, usually managing 24/seven in substantial-quantity options. Their toughness guarantees dependable general performance and trustworthiness, which happens to be important for retaining output schedules. It’s like using a significant-obligation truck that reliably delivers items day after working day.

On the list of amazing areas of laser slicing is its capability to create clean and specific edges. This lessens the need for publish-processing, such as sanding or ending, which may be time-consuming and costly. The result is usually a clean, finished product That always calls for minimum supplemental get the job done. Think about finishing a craft challenge without glue spills or rough edges—it’s that clear!